Calandrado is one of the most popular paper processing techniques today. It is used to improve paper properties and create paper products with greater gloss, smoothness and durability. In this article, we will learn about calandrado, from its implementation process to its applications and development trends.

What is Calandrado?

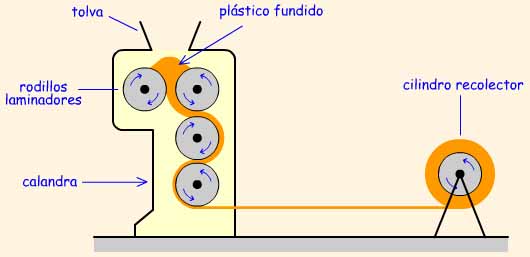

Calandrado is a papermaking technique using a calandre machine. A calandre is a type of press with two or more layers of rollers used to press paper between the layers of rollers to create high pressure and temperature. This process helps the paper compress and smooth the surface, creating paper products with different properties.

Advantages and disadvantages of calandrado

Like any machining technique, calandrado has its own advantages and disadvantages. Here are some highlights of calandrado:

Advantage:

- Create paper products with higher gloss, smoothness and durability.

- Improves paper properties such as flexibility, hardness and water resistance.

- Helps enhance the aesthetics of paper products.

- Enhances the anti-slip and anti-scratch properties of paper.

Defect:

- Initial investment costs for calandre machines and operating costs are high.

- High technical requirements and a team of skilled workers are required to carry out the calandrado process.

- Not suitable for papers with large thicknesses or high natural fiber content.

Different types of calandrado

There are three main types of calandrado used in papermaking: two-layer calandrado, three-layer calandrado and multi-layer calandrado.

Two-layer Calandrado

Two-layer Calandrado is the process of pressing paper between two layers of rollers. The top roller layer is called the calandre layer and the bottom roller layer is called the anti-press layer. This process helps create paper products with higher gloss and smoothness.

Three-layer Calandrado

Three-layer Calandrado is the process of pressing paper between three layers of rollers. The top roller layer is still the calandre layer, the middle roller layer is called the sub-press layer, and the bottom roller layer is still the anti-press layer. This process helps create paper products with superior properties with higher gloss, smoothness and durability.

Multilayer Calandrado

Multi-layer Calandrado is the process of pressing paper between multiple layers of rollers. The number of roller layers can be up to 8 or 10 layers. This process creates paper products with the highest gloss, smoothness and durability. However, this is also the type of calandrado with the highest investment and operating costs.

Calandrado process

The calandrado procedure includes the following steps:

- Prepare paper: Paper needs to be prepared before being put into the calandre machine. It must be cut into sheets of a certain size and thickness to ensure a smooth calandrado process.

- Feeding paper into the calandre machine: Paper is fed into the calandre machine through a transmission system and is pressed between layers of rollers.

- Pressure and temperature: Pressure and temperature are adjusted to achieve the best results during the paper pressing process.

- Removing the paper: After completing the pressing process, the paper is removed from the calandre machine and continues through the next processing steps.

Application of calandrado

Calandrado is widely used in papermaking to create paper products with superior properties. The main uses of calandrado include:

- Printing paper production: Calandrado helps enhance the aesthetics of printing paper, creating paper products with higher gloss and smoothness.

- Packaging paper production: Calandrado improves the properties of packaging paper such as flexibility, hardness and water resistance, helping to enhance the anti-slip and anti-scratch properties of the product.

- Toilet paper production: Calandrado helps create toilet paper products with greater smoothness and durability, while also improving the water absorption properties of paper.

Development trend of calandrado

With the continuous development of technology, calandrado is also being improved and developed to meet the increasing demand for paper production. Some development trends of calandrado are:

- Smart technology integration: Modern calandre machines are integrated with smart technology to automatically adjust pressure and temperature, helping to optimize the calandrado process and minimize human errors.

- Using environmentally friendly energy sources: Many manufacturers are focusing on using environmentally friendly energy sources to operate calandre machines, helping to minimize negative impacts on the environment.

- Improving performance and product quality: Manufacturers are researching and developing new types of calandre machines that can enhance performance and product quality.

Considerations when choosing a calandrado service provider

When deciding to use calandrado service, you need to keep in mind the following points to choose a reputable and quality supplier:

- Experience and expertise: Choose a supplier with experience and expertise in the field of calandrado to ensure the processing process goes smoothly and the product is of high quality.

- Technology and equipment: Ensure suppliers use modern machinery and technology to ensure accuracy and efficiency in the calandrado process.

- Product quality: Check the supplier’s previously calandrado products to evaluate the quality and aesthetics of the product.

- After-sales service: Choose a supplier with good after-sales service to ensure satisfaction and support when needed.

Calandrado cost

The cost of calandrado depends on many factors such as the type of calandrado, size and thickness of the paper, number of products to be processed, etc. However, this cost is often quite high due to high technical requirements and demanding use. Using modern machinery and technology.

The role of calandrado in paper production

Calandrado plays an important role in the paper production process. It helps improve the properties of paper and create products with superior properties, thereby enhancing the competitiveness of businesses and meeting market needs.

Calandrado and other paper processing techniques

Besides calandrado, there are many other paper processing techniques used in paper production such as lamination, heat pressing, etc. Each technique has its own advantages and disadvantages and is often used in combination to create products. Paper has the best properties.

Conclude

Calandrado is one of the most important and popular paper processing techniques today. It plays an important role in improving paper properties and creating paper products with higher gloss, smoothness and durability. However, to achieve optimal efficiency from calandrado, you need to choose a reputable and quality supplier, while ensuring reasonable costs and in accordance with the production needs of your business. Hopefully this article has helped you better understand calandrado and its role in paper production. The supplier uses modern machinery and technology to ensure accuracy and efficiency in the calandrado process.

- After-sales service: Choose a supplier with good after-sales service to ensure satisfaction and support when needed.

Calandrado cost

The cost of calandrado depends on many factors such as the type of paper, size and thickness of the paper, the number of products to be processed, the difficulty of the calandrado process, etc. However, the initial investment cost for the calandre machine and High operating costs are the main factors affecting calandrado costs.

The role of calandrado in paper production

Calandrado plays an important role in creating paper products with superior properties and meeting the increasing demands of the market. It helps improve paper properties and enhances aesthetics, and is also an important step in the paper production process.

Calandrado and other paper processing techniques

Besides calandrado, there are many other paper processing techniques such as hot pressing, cold pressing, coating, etc. Each technique plays an important role in creating high quality paper products. Depending on the intended use and nature of the paper product, these techniques can be used individually or in combination to create the final product.

Conclude

Calandrado is an important process in paper production, helping to create paper products with superior properties and meeting increasing market demands. However, it also has advantages and disadvantages that need to be considered when used. Choosing a reputable and quality calandrado service provider is also important to ensure efficiency and final product quality.